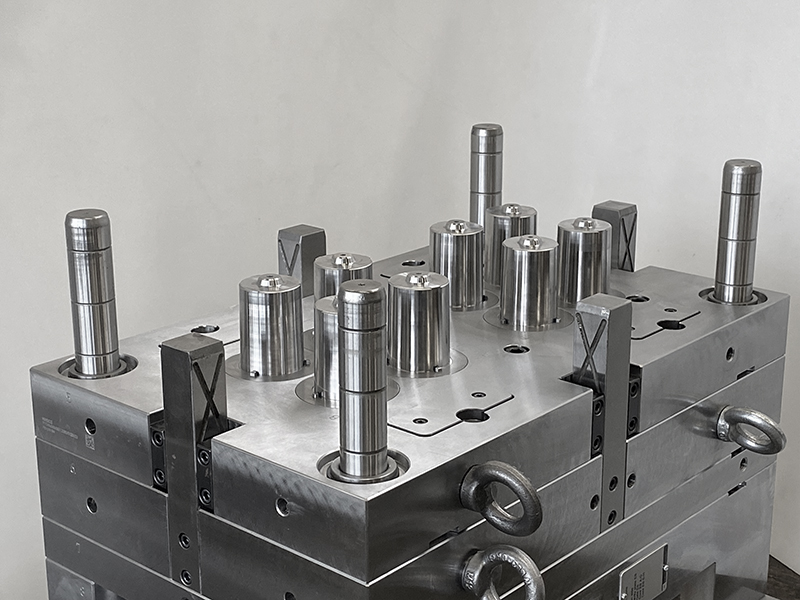

Injection Moulds

- Multi-cavity moulds with over 100 mould cavities

- Full interchangeability of mould inserts with each other (modularity)

- Unscrewing moulds, also multiple

- Complex slide solutions (curved, underfloor and profile slides, screw, decay and expanding cores)

- Mechanical, hydraulic and electrical actuation concepts

- Solutions with inserts for high levels of automation

- Moulds for special articles in small quantities

- We realize the optimum hot runner solution for you, from single nozzles to multiple manifolds and special solutions, such as lateral connection in multi-cavity moulds.